Welcome to Dinesh Ispat Pvt. Ltd

Facilities / QA

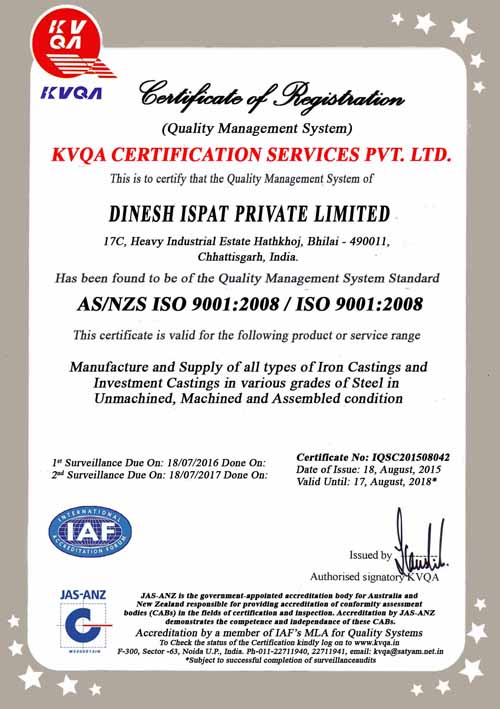

We are Accredited with ISO 9001:2008 by KVQA.

Investment Casting Facility Equipped with:

- Semi-Automatic Wax Injection Presses (12T, 20T & 25T).

- State-of-art Shelling area having complete control on Temperature & Humidity.

- Electrically Heated Autoclave for dewaxing

- IGBT Induction furnace: 250 KW with 150 kg & 300 kg crucibles.

- Electrical Heat-Treatment Furnace with Computer control & Monitoring system with maximum temperature of 1250oC with Auto-Quenching facility.

- Well-equipped fettling & finishing area.

Alloy Iron Foundry Equipped with:

- Induction Furnace: 2750 KW with 2 Crucibles of 6 MT each.

- Pneumatic Sand Conveying Systems

- Overhead cranes

- Sand Batch Mixers

- Sand Dryer & Sieving System

- Ladles of Several sizes and types

- Power backup with 2 Silent DG Sets (200 KVA & 125 KVA)

QA/QC Facilities include:

- Optical Emission Spectrometer with all required Standard Samples.

- Universal Tensile Testing Machine

- Impact Testing Machine

- Hardness Testing Machine (Brinell & Rockwell)

- Metallographic Microscope

- Chemical (Wet) analysis laboratory

- Sand Testing Laboratory

- Measuring Instruments & Gauges

- Magnetic Particle testing- ASNT Level II

- Dye (Liquid) penetrant test facilities.- ASNT Level II

- Metallographic Laboratory

- Facilities for Surface Treatment

- In-House Machining facilities: CNC & Conventional